Tungsten sheet is a thin, flat metal material made from tungsten, known for its high density, strength, and exceptional heat resistance. It is created in sheet form to provide a versatile and durable material for applications such as electrical contacts, heating elements, radiation shielding, and various industrial uses requiring robust and reliable metal components. Read More…

When you need specialty metals, run of the mill products or hard to find alloys contact Metal Associates. We are a full line distributor of metals such as aluminum. These include aluminum strip, aluminum bar, aluminum rods, 6061 aluminum, 7075 aluminum, aluminum coil, aluminum sheet, aluminum pipe, aluminum plate & aluminum tubing. We offer quality customer service & high quality products.

Elmet Technologies LLC is a 100% US owned and operated, fully integrated manufacturer of molybdenum, tungsten products and alloys. Elmet produces both flat and long/round mill products, including plate, sheet, and foil, flat rolled products, rod and wire. We have industry leading machining, fabrication, and assembly capabilities. We are a specialty metals business with over 85 years of molybdenum ...

At All Metal Sales Inc., we take pride in delivering high-quality tungsten to meet the demanding needs of industries that require exceptional strength and performance. We specialize in sourcing and distributing tungsten in a variety of forms, from raw materials to precision-engineered components, ensuring our customers receive products that excel in durability, heat resistance, and density.

At H. Cross Company, we pride ourselves on being a leading force in the fabrication and supply of precision tungsten components. With decades of experience behind us, we’ve built our reputation on the strength, reliability, and unmatched performance of our tungsten products. We understand the critical role this refractory metal plays across a wide range of demanding applications—from...

At Buffalo Tungsten, we take pride in being a leading manufacturer of high-purity tungsten powder and related products for customers around the world. We specialize in producing tungsten powders that meet the precise requirements of industries where performance, consistency, and purity are critical.

More Tungsten Sheet Suppliers

Creation of Tungsten Sheet

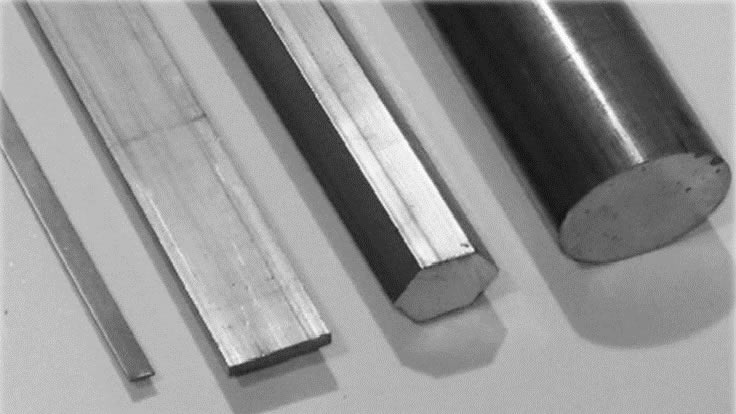

Tungsten sheet, a core form of wrought tungsten product, is produced through a series of advanced tungsten manufacturing processes designed to optimize its unique properties for critical industrial and commercial applications. The creation of tungsten sheet typically begins with the selection of high-purity tungsten powder, which is then subjected to various methods such as sintering, rolling, forging, and annealing. Each method is chosen based on intended use, required sheet thickness, and end-user specifications.

Sintering is a widely used production technique where powdered tungsten is compacted under high pressure and heated just below its melting point. This process causes the particles to bond, creating a dense, strong sheet with excellent structural integrity. Sintered tungsten sheets are especially popular in the creation of electrical contacts and semiconductor components, where both conductivity and mechanical strength are vital.

Rolling and annealing processes further refine tungsten sheets. After initial sintering, the tungsten billet is hot-rolled and then cold-rolled to achieve precise thickness and a smooth surface finish. Annealing—controlled heating followed by slow cooling—relieves internal stresses and enhances ductility, making these sheets ideal for heating elements, vacuum furnace components, and high-temperature fixtures.

Additionally, powder metallurgy is an effective approach for producing custom tungsten sheets, especially those intended for radiation shielding or x-ray protection. This method allows for the incorporation of alloying elements such as nickel, copper, or silver to tailor properties like thermal conductivity or machinability. Are you interested in learning how tungsten sheet is engineered for your industry-specific needs? Explore detailed use cases below.

Regulations and Standards for Tungsten Sheet

When considering the procurement or application of tungsten sheet, understanding relevant regulations and industry standards is essential for ensuring compliance, safety, and quality. In the United States, tungsten sheet production is governed by a suite of federal, state, and industry-specific regulations designed to protect workers, end-users, and the environment.

One of the primary regulatory frameworks is the Toxic Substances Control Act (TSCA), administered by the United States Environmental Protection Agency (EPA). The TSCA dictates the manufacture, import, processing, distribution, and use of chemical substances—including tungsten and its compounds. Manufacturers and importers of tungsten-based materials, such as tungsten sheet, are required to submit pre-manufacture notifications to the EPA before introducing new substances into the market. This process ensures that potential environmental and health risks are thoroughly evaluated and managed.

In addition, the Occupational Safety and Health Administration (OSHA) sets forth standards to protect workers in tungsten sheet manufacturing environments. These cover a broad range of occupational safety topics, including:

- Occupational exposure limits for tungsten dust and fumes

- Respiratory protection protocols

- Personal protective equipment (PPE) requirements

- Hazard communication and labeling standards

- Safe handling and storage of tungsten sheet and related chemicals

Furthermore, the tungsten industry often adheres to international material standards, such as ASTM B760 for wrought tungsten products, which defines chemical composition, mechanical properties, and testing procedures. Compliance with these standards is crucial for applications in aerospace, medical devices, and electronics.

Regulatory requirements for tungsten sheet are dynamic and subject to change. Manufacturers and buyers are encouraged to stay informed by consulting regulatory agencies such as the EPA, OSHA, and relevant industry associations. Want to know if your tungsten sheet supplier meets the latest certifications? See our guide for selecting a compliant manufacturer.

Considerations Regarding Tungsten Sheet

While tungsten sheet excels in performance and durability, buyers and specifiers must consider several important factors before selecting a supplier or product grade. Environmental impact, health and safety concerns, and cost-effectiveness are among the key decision-making criteria.

Environmental impacts of tungsten extraction and processing include high energy consumption and the potential release of hazardous byproducts. Responsible tungsten sheet manufacturers implement closed-loop systems, invest in renewable energy, and adopt advanced filtration technologies to minimize their ecological footprint.

Health considerations are also critical. Tungsten in sheet form is generally stable and non-toxic, but during processing—such as cutting, grinding, or welding—tungsten dust or fumes may pose inhalation risks. Employers must provide proper ventilation and personal protection for workers. For design engineers and procurement teams, understanding these considerations helps mitigate risks and supports responsible sourcing.

Cost is another consideration. While tungsten sheet price is higher than more common metals, its unparalleled performance in demanding environments often delivers lower total cost of ownership. Interested in comparing tungsten sheet with alternative materials for your project? Review the benefits and applications below to see if tungsten sheet is right for you.

The Response of Tungsten Sheet Manufacturers

To address growing concerns about sustainability and operational efficiency, leading tungsten sheet manufacturers are investing heavily in research and development aimed at cleaner, safer, and more efficient production methods. Modern manufacturing facilities routinely implement:

- State-of-the-art waste management systems to reduce hazardous byproducts

- Energy recovery and recycling processes for scrap tungsten and spent materials

- Water conservation strategies to minimize industrial water use

- Continuous process optimization to lower emissions and improve yield

- Collaboration with regulatory agencies to ensure ongoing compliance and innovation

Manufacturers also engage in life-cycle analysis to measure and improve the environmental performance of tungsten sheet throughout its supply chain. These initiatives not only ensure regulatory compliance but also enhance the reputation and reliability of suppliers in competitive markets. Curious about how manufacturers are making tungsten sheet production more sustainable? Discover the latest trends and innovations below.

Benefits of Tungsten Sheet

Tungsten sheet offers a unique combination of properties that make it indispensable in advanced engineering and technology applications. Some of the primary benefits include:

- High density and strength – With a density of 19.3 g/cm³, tungsten sheet provides exceptional mass and impact resistance, making it perfect for ballast, counterweight, and penetrator applications.

- Superior heat resistance – Tungsten maintains its structural integrity at temperatures exceeding 3,400°C, making it ideal for high-temperature environments such as furnace linings, rocket nozzles, and industrial heating elements.

- Excellent corrosion and wear resistance – Tungsten’s resistance to most acids and aggressive environments ensures a long service lifespan, even under severe operating conditions.

- Outstanding electrical and thermal conductivity – These properties are critical for semiconductor fabrication, heat sinks, and electrical contacts.

- Radiation shielding – Tungsten’s high atomic number and density provide effective protection from X-rays and gamma rays, making it a preferred material for medical imaging and nuclear containment.

- Low coefficient of thermal expansion – This ensures dimensional stability over a wide temperature range, which is essential for precision components.

- Customizability – Available in a variety of thicknesses, widths, and surface finishes to meet diverse application requirements.

Need more information on tungsten sheet advantages for your specific application? Jump to the applications section to explore use cases by industry.

Applications of Tungsten Sheet

Tungsten sheet’s exceptional properties drive its widespread adoption across a multitude of industries, from defense and aerospace to electronics, medical, and energy sectors. Here’s how tungsten sheet is used in key markets:

Aerospace and Defense

- Aircraft components – Used in control surfaces, ballast weights, and aerodynamic counterbalances due to its mass and dimensional stability.

- Radiation shielding – Protects sensitive avionics and crew from cosmic and nuclear radiation.

- Armor-piercing projectiles and kinetic energy penetrators – Tungsten’s density and hardness provide superior penetration and survivability.

Medical and Healthcare

- X-ray targets – High melting point and atomic number make tungsten sheet ideal for X-ray generation equipment.

- Radiation therapy equipment – Employed in collimators, shields, and apertures to precisely direct and block radiation.

- Medical imaging devices – Used as shielding and in anti-scatter grids in CT and fluoroscopy systems.

Electronics and Electrical Engineering

- Semiconductor fabrication – Tungsten sheet is an essential material for back-end-of-line metallization and chip interconnects.

- Electrical contacts and relays – Provides reliable performance under high-voltage, high-current conditions.

- Vacuum furnace elements – Resists heat and maintains conductivity in ultra-high-vacuum environments.

Industrial and Energy

- High-temperature furnace linings – Withstands aggressive thermal cycling and chemical exposure.

- Solar and nuclear power – Used in shielding, containment, and heat management systems.

- Lighting and electronic devices – Used in filaments, electrodes, and thermal management components.

Emerging and Custom Applications

- 3D printing and additive manufacturing – Thin tungsten sheet and foil are used as feedstock for advanced fabrication methods.

- Automotive and transportation – Applied in hybrid vehicle battery shielding and weight balancing.

- Scientific research – Utilized in particle accelerators, detectors, and experimental apparatus requiring radiation resistance and precision.

Have a unique application? Contact leading tungsten sheet suppliers to discuss custom solutions and fabrication options.

The Future and Tungsten Sheet

The outlook for tungsten sheet is exceptionally bright as technological innovation, sustainability, and global demand converge. Ongoing research and development is focused on enhancing the mechanical properties, purity, and fabrication techniques for tungsten sheet, enabling new applications in quantum computing, electric vehicles, green energy production, and advanced medical therapies.

As industries place increasing emphasis on environmental responsibility, tungsten sheet manufacturers are adopting greener production methods, including:

- Closed-loop recycling of tungsten scrap to reduce reliance on primary raw materials

- Lower-emission sintering and melting technologies

- Supply chain transparency and conflict-free sourcing of tungsten ore

- Collaboration with end-users to design for recyclability and reduced resource consumption

Do you want to stay ahead of tungsten sheet trends and innovations? Partner with manufacturers who prioritize R&D and sustainability.

Choosing the Right Tungsten Sheet Manufacturer

Selecting the optimal tungsten sheet supplier is a critical step for ensuring reliable performance, consistent quality, and regulatory compliance. Here’s how to make an informed decision:

- Use our comprehensive directory of tungsten sheet manufacturers to compare certified suppliers. Each business profile page highlights their core competencies, certifications (such as ISO 9001), and technical expertise.

- Review supplier capabilities, including minimum and maximum sheet thicknesses, surface finish options, and custom fabrication services.

- Evaluate the manufacturer’s experience in your target application—whether for aerospace, medical, electronics, or energy markets.

- Request samples and material certifications (such as ASTM or AMS specs) to verify quality and traceability.

- Use our RFQ (Request for Quote) form to submit your requirements to multiple suppliers at once, streamlining your procurement process and ensuring competitive pricing.

For more insights, consider these common search questions:

- What is the price of tungsten sheet per kilogram or per square meter?

- Which tungsten sheet supplier offers custom cutting and machining?

- How do I specify tungsten sheet thickness and surface finish?

- What certifications should a tungsten sheet manufacturer have?

- Is recycled tungsten sheet available for sustainable projects?

- How does tungsten sheet compare to molybdenum or tantalum sheets?

Looking to purchase tungsten sheet for your next project? Browse our directory, compare manufacturers, and request a quote to get started.

Conclusion: Unlocking Performance with Tungsten Sheet

Tungsten sheet stands as a premier material solution for engineers, designers, and manufacturers seeking unmatched performance in demanding environments. Its unique blend of high density, extraordinary heat resistance, corrosion resilience, and customizability drives innovation across industries from aerospace and defense to healthcare, electronics, and beyond.

By understanding the intricacies of tungsten sheet manufacturing, staying current on regulations and standards, and carefully selecting a trusted supplier, you can ensure the success and sustainability of your project. Whether you need precision-cut tungsten sheet for a semiconductor device, radiation shielding tungsten sheet for a medical facility, or custom tungsten alloy sheets for a new product development, the right partner makes all the difference.

Ready to take the next step? Find a tungsten sheet manufacturer in our trusted directory, or request a quote today to unlock the full benefits of this exceptional engineered material.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services