Tungsten is a chemical element with the symbol W and atomic number 74. It is a dense, grayish-white metal that possesses exceptional properties making it highly valuable and important in various industries. Read More…

When you need specialty metals, run of the mill products or hard to find alloys contact Metal Associates. We are a full line distributor of metals such as aluminum. These include aluminum strip, aluminum bar, aluminum rods, 6061 aluminum, 7075 aluminum, aluminum coil, aluminum sheet, aluminum pipe, aluminum plate & aluminum tubing. We offer quality customer service & high quality products.

Elmet Technologies LLC is a 100% US owned and operated, fully integrated manufacturer of molybdenum, tungsten products and alloys. Elmet produces both flat and long/round mill products, including plate, sheet, and foil, flat rolled products, rod and wire. We have industry leading machining, fabrication, and assembly capabilities. We are a specialty metals business with over 85 years of molybdenum ...

At All Metal Sales Inc., we take pride in delivering high-quality tungsten to meet the demanding needs of industries that require exceptional strength and performance. We specialize in sourcing and distributing tungsten in a variety of forms, from raw materials to precision-engineered components, ensuring our customers receive products that excel in durability, heat resistance, and density.

At H. Cross Company, we pride ourselves on being a leading force in the fabrication and supply of precision tungsten components. With decades of experience behind us, we’ve built our reputation on the strength, reliability, and unmatched performance of our tungsten products. We understand the critical role this refractory metal plays across a wide range of demanding applications—from...

At Buffalo Tungsten, we take pride in being a leading manufacturer of high-purity tungsten powder and related products for customers around the world. We specialize in producing tungsten powders that meet the precise requirements of industries where performance, consistency, and purity are critical.

More Tungsten Suppliers

How Is Tungsten Mined?

Tungsten, also known as wolfram, is primarily sourced from scheelite and wolframite mineral deposits found worldwide, with leading tungsten production concentrated in countries such as China, Russia, Canada, and Bolivia. These tungsten-bearing minerals serve as the backbone of the global tungsten supply chain, fueling applications in high-performance manufacturing, electronics, defense, and energy sectors. Scheelite (CaWO4) is often found in various colors and crystal forms within hydrothermal veins and greisen-type ore bodies, while wolframite ((Fe,Mn)WO4) typically appears as black or brown tabular crystals in quartz veins and granitic pegmatites. Both are essential for industrial use because of their high tungsten content and favorable mining characteristics.

The tungsten mining process is a multi-stage operation that involves several critical steps to ensure efficient and responsible extraction. The initial step is prospecting, where geologists conduct surveys and exploratory drilling to locate and map economically viable tungsten ore bodies. Once identified, extraction follows, utilizing either open-pit mining for shallow deposits or underground mining techniques for deeper, less accessible ore. Open-pit mining uses heavy earth-moving machinery such as excavators, loaders, and haul trucks, while underground mining involves complex tunneling and drilling operations.

After extraction, the raw tungsten ore undergoes crushing and grinding to liberate the tungsten minerals from surrounding rock. The next phase, beneficiation, separates tungsten from waste material (gangue) using advanced concentration methods such as gravity separation, froth flotation, and magnetic separation—the choice of method depends on the mineralogy and particle size. The resulting tungsten concentrate is then roasted at high temperatures, a process which removes residual impurities and converts the mineral to tungsten oxide (WO3). The final refining step reduces tungsten oxide to pure tungsten powder or ingots through high-temperature hydrogen reduction or other metallurgical processes, readying it for downstream industrial applications.

For readers interested in the full lifecycle of tungsten—from ore to finished product—explore: What are the best practices in tungsten processing and refining?

Common Tungsten Forms and Their Industrial Uses

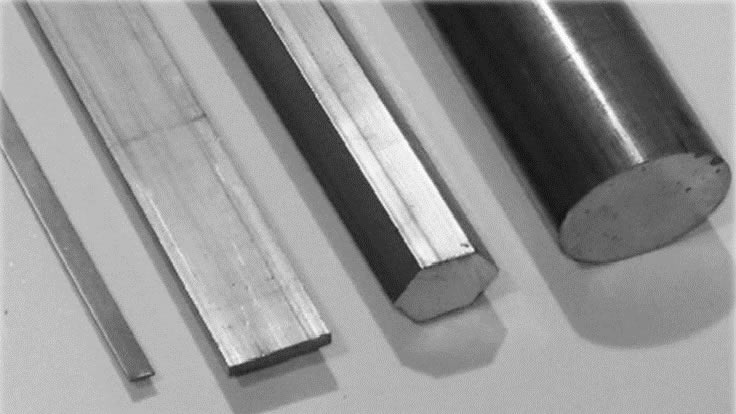

Tungsten is supplied in a wide array of forms, each tailored to meet specific industrial needs and material requirements. The most prevalent forms include:

- Tungsten Oxide (WO3): Produced during the primary refinement of tungsten ore, this yellowish or bluish powder serves as a key precursor for the production of pure tungsten metal. It is also vital in the manufacturing of tungsten alloys, ceramic pigments, and as a catalyst in various chemical processes.

- Tungsten Carbide (WC): A synthetically produced compound combining tungsten and carbon, tungsten carbide is renowned for its extreme hardness and abrasion resistance. It is widely utilized in the fabrication of cutting tools, end mills, drill bits, mining tools, saw blades, and industrial wear parts—making it an indispensable choice in sectors like metalworking, mining, oil and gas, and construction.

- Tungsten Alloys: These are engineered by combining tungsten with metals such as nickel, copper, iron, or cobalt. Tungsten alloys are valued for their high density, mechanical strength, and superior thermal and electrical conductivity. They are extensively used in aerospace, defense (e.g., kinetic energy penetrators, counterweights), electrical contacts, X-ray and gamma-ray shielding, and medical imaging devices.

- Pure Tungsten Metal: Available as rods, wires, sheets, bars, and custom machined components, pure tungsten is essential for high-temperature applications such as lamp filaments, electron emitters, and furnace components due to its unmatched melting point and low vapor pressure.

- Tungsten Powder: Used as a raw material in powder metallurgy for producing sintered parts, electrical contacts, and specialized coatings, tungsten powder is a foundational material for advanced manufacturing processes.

Considerations with Tungsten

Mining and utilizing tungsten involves multiple critical considerations that impact environmental sustainability, worker safety, and supply chain responsibility. Below, we outline the key factors to evaluate when sourcing or using tungsten for your operations:

- Environmental Impact: Without proper regulation and oversight, tungsten mining can result in habitat destruction, soil erosion, water contamination from tailings and chemical runoff, and landscape alteration. The extraction and beneficiation processes are energy-intensive, potentially increasing the carbon footprint and greenhouse gas emissions associated with tungsten production. Responsible tungsten mining operations now prioritize land reclamation, water management, and pollution mitigation to minimize their environmental footprint.

- Worker Health and Safety: Both underground and open-pit mining environments present inherent risks, including rock falls, cave-ins, exposure to dust and hazardous chemicals, and injuries from heavy machinery. Ensuring the health and safety of miners requires strict adherence to occupational health standards, comprehensive safety training, and investment in protective equipment and emergency response protocols.

- Social and Ethical Sourcing: Tungsten is classified as a potential conflict mineral, particularly when sourced from regions affected by armed conflict or human rights abuses. It is vital for companies to implement transparent supply chain management and traceability measures to avoid supporting conflict financing or unethical labor practices. This includes rigorous supplier vetting, compliance with international standards, and periodic supply chain audits.

Manufacturers Address These Considerations

Leading tungsten manufacturers are increasingly proactive in addressing the environmental, social, and ethical challenges associated with tungsten mining and production. Here’s how responsible suppliers are setting higher standards:

- Environmental Stewardship: Manufacturers invest in land restoration and mine site rehabilitation after resource extraction, employ advanced water recycling systems, and manage waste byproducts to prevent pollution and ecosystem disruption. Adopting energy-efficient technologies and renewable energy sources in processing plants helps to reduce the overall carbon footprint of tungsten production.

- Worker Safety and Community Engagement: Leading suppliers enforce rigorous occupational safety programs, offer continuous employee training, and provide access to personal protective equipment. Beyond compliance, manufacturers support community development initiatives, invest in local infrastructure, and foster open dialogue with stakeholders to maintain a positive relationship with host communities.

- Ethical Supply Chains: Responsible tungsten producers adhere to international regulations, such as the Dodd-Frank Act’s conflict minerals provisions, and participate in third-party certification schemes like the Responsible Minerals Initiative (RMI) or OECD Due Diligence Guidance. Transparent reporting practices, supply chain traceability, and regular audits are cornerstones of their ethical sourcing programs.

- Innovation for Sustainability: Many manufacturers are researching and deploying cleaner extraction methods, such as bioleaching and hydrometallurgy, to reduce reliance on hazardous chemicals and minimize environmental harm. Investments in closed-loop recycling and recovery of tungsten from scrap materials further support resource conservation and circular economy principles.

- Industry Collaboration: Partnerships with non-governmental organizations (NGOs), industry associations, and research institutions drive continuous improvement in environmental management, social responsibility, and supply chain transparency. By sharing best practices and collaborating on standards development, the tungsten industry advances collective sustainability goals.

Want to learn how manufacturers demonstrate responsible sourcing? Explore tungsten supplier certifications and standards.

Regulations for Tungsten

In the United States and globally, tungsten is regulated to ensure ethical sourcing, avoid the use of conflict minerals, and promote environmental stewardship. The most prominent regulation in the U.S. is the Dodd-Frank Wall Street Reform and Consumer Protection Act, with Section 1502 specifically targeting conflict minerals—tungsten, tin, tantalum, and gold—sourced from countries such as the Democratic Republic of the Congo (DRC) and its neighbors.

Under Dodd-Frank, publicly traded companies must:

- Disclose their use of tungsten and other conflict minerals in products.

- Conduct comprehensive supply chain due diligence to trace the origin of minerals.

- Submit annual conflict minerals reports to the U.S. Securities and Exchange Commission (SEC).

- Demonstrate efforts to ensure minerals are sourced from conflict-free suppliers.

Globally, organizations such as the Responsible Minerals Initiative (RMI) and the Organization for Economic Cooperation and Development (OECD) provide frameworks and guidance for supply chain due diligence, helping companies to map their suppliers, identify risks, and implement corrective actions to ensure responsible sourcing.

Applications of Tungsten

Tungsten’s unique material properties—high density, exceptional hardness, superior thermal and electrical conductivity, and outstanding resistance to heat and wear—make it indispensable across a diverse range of industries. Here are some of the most important uses for tungsten and its alloys:

- Metalworking and Manufacturing: Tungsten carbide is the material of choice for precision cutting tools, metalworking inserts, saw blades, and wear-resistant components. Its unrivaled hardness and toughness enable efficient machining of hard metals and alloys, extending tool life and reducing downtime.

- Electronics and Lighting: Pure tungsten wire is used in light bulb filaments, electron emitters, and heating elements, leveraging its ability to withstand extremely high temperatures without oxidizing or deforming.

- Aerospace and Defense: Tungsten’s high melting point and density make it ideal for aerospace applications such as rocket nozzles, ballast weights, counterbalances, and high-performance penetrators. Tungsten alloys are used in kinetic energy projectiles, fragmentation devices, and armor-piercing ammunition for military applications.

- Medical Imaging and Radiation Shielding: Tungsten shielding is essential in X-ray and gamma-ray protection for medical imaging rooms, nuclear medicine equipment, and radiation therapy devices. Its high atomic number and density provide superior attenuation of harmful radiation while minimizing shield thickness.

- Electrical Contacts and Power Transmission: Tungsten is used in electrical contacts, switchgear, and circuit breakers due to its high conductivity, resistance to electrical arcing, and stability under heavy load conditions.

- Balance and Counterbalance Systems: The high density of tungsten alloys allows for compact and effective counterweights in aircraft, helicopters, automotive crankshafts, and industrial machinery.

- Sports and Leisure: Tungsten is used in darts, golf club weights, and fishing sinkers, providing high mass in small volumes for precision and performance.

Tungsten in the Energy Sector

Tungsten’s role in the global energy sector is expanding rapidly, driven by the shift toward sustainable and renewable energy technologies. Its material properties make it vital for:

- Wind Power Generation: Tungsten’s exceptional strength, density, and resistance to fatigue make it ideal for use in wind turbine blades and generator components. Tungsten carbide coatings on critical parts reduce wear, extend operational life, and improve the reliability of wind turbines.

- Energy Storage: In lithium-ion and other advanced batteries—essential for electric vehicles (EVs) and grid storage—tungsten is used in anodes and current collectors to enhance conductivity, improve charge/discharge cycles, and increase battery efficiency.

- Solar Energy: Tungsten’s high melting point and reflectivity are leveraged in solar thermal collectors, mirrors, and components for concentrated solar power (CSP) systems, where durability and heat resistance are crucial for sustained performance.

- Fossil Fuels and Nuclear Power: In oil and gas drilling, tungsten carbide drill bits withstand harsh downhole conditions. In nuclear power plants, tungsten alloys provide critical shielding for radioactive materials and high-energy particles.

If you’re evaluating tungsten for energy sector applications, consider: How does tungsten improve renewable energy performance?

What Does the Future of Tungsten Look Like?

The future outlook for tungsten is exceptionally strong, with sustained global demand anticipated due to its unique properties and expanding applications. Several factors are shaping the tungsten market and industry trends:

- Technological Advancements: The rise of smart manufacturing, Industry 4.0, and automation is increasing the need for high-performance machining tools and wear-resistant parts, driving tungsten consumption in advanced manufacturing.

- Growth in Renewable Energy and Electric Vehicles: As the world transitions to cleaner energy, the demand for tungsten in wind turbines, solar power systems, and battery technologies is accelerating. Tungsten’s role in enhancing energy efficiency and sustainability is becoming more prominent.

- Medical and Healthcare Innovation: With ongoing advancements in medical imaging, diagnostics, and radiation therapy, tungsten’s importance in shielding and specialized equipment will continue to grow.

- Focus on Responsible Mining and Circular Economy: There is a strong industry push toward sustainable mining, recycling of tungsten-containing scrap, and closed-loop manufacturing to minimize waste and reduce environmental impact. Circular economy initiatives are expected to improve resource efficiency and supply chain resilience.

- Supply Chain Diversification: Efforts are underway to diversify sources of tungsten and develop new mining projects outside of traditional regions, reducing geopolitical risks and securing stable supply for critical industries.

Choosing the Correct Tungsten Supplier

Selecting the right tungsten supplier is crucial for ensuring quality, reliability, and value in your supply chain. Here’s how our directory streamlines the purchasing process and supports your decision-making:

- Comprehensive Supplier Profiles: Each listing details the supplier’s expertise, product offerings, certifications, and industry focus, making it easy to compare capabilities and specialization areas.

- Direct Communication: Built-in contact forms enable you to submit inquiries or request quotes directly from suppliers, saving time and facilitating prompt responses.

- Website Previewer: Our patented tool allows you to preview supplier websites instantly, helping you assess their quality standards, manufacturing capabilities, and company values at a glance.

- Streamlined RFQ Process: Use our multi-supplier RFQ form to reach out to several tungsten vendors simultaneously—ideal for competitive bidding and sourcing efficiency.

- Guidance and Resources: Access helpful guides on tungsten grade selection, quality assurance, and import/export compliance to inform your purchasing decisions.

Frequently Asked Questions About Tungsten

- What are the main factors influencing tungsten prices? Supply-demand balance, geopolitical risks, mining and processing costs, recycling rates, and regulatory changes all impact tungsten pricing.

- How can I verify if a tungsten supplier is conflict-free? Look for suppliers participating in recognized certification schemes such as the Responsible Minerals Initiative (RMI) and request documentation of compliance with Dodd-Frank or OECD guidelines.

- What are the most common tungsten grades and how do I select the right one? Selection depends on your application’s requirements for hardness, toughness, conductivity, and corrosion resistance.

- Can tungsten be recycled? Yes, tungsten scrap and used carbide tools can be efficiently recycled, reducing environmental impact and supporting a circular supply chain. Learn more at tungsten recycling options.

- What is the minimum order quantity (MOQ) for tungsten products? MOQs vary by supplier, product form, and customization level. Contact suppliers directly for specific order requirements and lead times.

Next Steps: Source High-Quality Tungsten for Your Business

Ready to source tungsten products for your manufacturing, energy, aerospace, or medical applications? Our supplier directory connects you with top-rated tungsten manufacturers and distributors, supporting projects of any scale. Whether you need tungsten carbide for tooling, pure tungsten wire for electronics, or custom tungsten alloys for specialized use, our streamlined search, comparison, and RFQ tools make the process efficient and transparent.

Explore our full list of tungsten suppliers and take the next step toward reliable, ethically sourced, and high-performance tungsten solutions tailored to your industry needs.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services