Tungsten rods are pre-formed pieces of tungsten that are machined or ground into components and goods. Read More…

When you need specialty metals, run of the mill products or hard to find alloys contact Metal Associates. We are a full line distributor of metals such as aluminum. These include aluminum strip, aluminum bar, aluminum rods, 6061 aluminum, 7075 aluminum, aluminum coil, aluminum sheet, aluminum pipe, aluminum plate & aluminum tubing. We offer quality customer service & high quality products.

Elmet Technologies LLC is a 100% US owned and operated, fully integrated manufacturer of molybdenum, tungsten products and alloys. Elmet produces both flat and long/round mill products, including plate, sheet, and foil, flat rolled products, rod and wire. We have industry leading machining, fabrication, and assembly capabilities. We are a specialty metals business with over 85 years of molybdenum ...

At All Metal Sales Inc., we take pride in delivering high-quality tungsten to meet the demanding needs of industries that require exceptional strength and performance. We specialize in sourcing and distributing tungsten in a variety of forms, from raw materials to precision-engineered components, ensuring our customers receive products that excel in durability, heat resistance, and density.

At H. Cross Company, we pride ourselves on being a leading force in the fabrication and supply of precision tungsten components. With decades of experience behind us, we’ve built our reputation on the strength, reliability, and unmatched performance of our tungsten products. We understand the critical role this refractory metal plays across a wide range of demanding applications—from...

At Buffalo Tungsten, we take pride in being a leading manufacturer of high-purity tungsten powder and related products for customers around the world. We specialize in producing tungsten powders that meet the precise requirements of industries where performance, consistency, and purity are critical.

More Tungsten Rod Suppliers

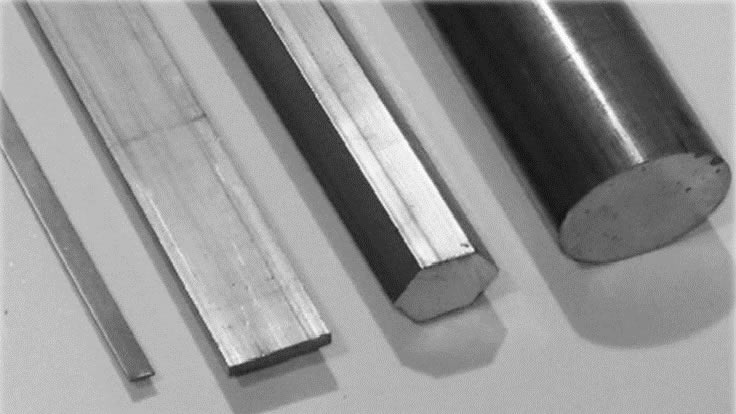

Types Of Tungsten Rods

Tungsten Heavy Alloy Rod (WNiFe/WNiCu Rod)

The liquid-phase sintering process creates a tungsten heavy (also known as "high density") alloy rod. This rod is 85-99% pure tungsten. In addition to its extremely high density (16.5g/cc to 19.0g/cc), tungsten heavy alloy rod is coveted for its superior strength, less thermal expansion, and easier machinability than pure tungsten rod.

Tungsten Copper Rod (W Cu Rod)

Tungsten copper rods have excellent conductivity and resistance to electrical erosion. While the infiltrated copper has a special cooling effect, when working temperatures reach as high as 2000°C, the rod relies on the tungsten skeleton structure to give it strength. A tungsten copper rod is produced using the infiltration sintering process in a fractional range of W Cu 50/50 to W Cu 90/10. Due to their unique variances in melting point, density, and numerous other physical characteristics, tungsten and copper cannot be combined. Different metal component ratios will create specific physical and mechanical qualities.

Lanthanated Tungsten Rod (W La Rod)

The dispersion strengthening method dopes lanthanum oxide into pure tungsten to create a lanthanide tungsten rod. The lanthanum oxides improve the alloy's heat resistance, conductivity, and crystallization temperature beyond a pure tungsten rod. As a result, the lanthanide tungsten rod is the recommended electrode material in both DC and AC welding operations. A lanthanide tungsten rod has excellent arc stability at low amperages, a minimal burn rate in high amperage conditions, good current carrying capability, little spark erosion, and poses no radioactive risks.

Tungsten Rods Manufacturing Process

Raw material

The mineral that contains tungsten is called Sheelite or wolframite. Ammonium-Para Tungsten is the initial raw material used in the manufacturing process. The initial part of the process, known as the "Wet" process, entails a series of precipitations, separations, and dissolutions.

Reduction

The APT is heat reduced in hydrogen to produce pure tungsten powder (W). The grain size of the tungsten power can be changed between 1 and 20 um by altering the reduction process.

Carburization

Carbon and tungsten are combined in the correct ratios. Then, high-temperature hydrogen is used to heat the mixture while tungsten carbide powder forms (WC).

Ingredient Weigh-In

Various WC powders and binder Cobalt (Co) powder are considered for cemented carbide production. The mixture is wet milled after the WC, Co, and other additives have been weighed in according to the specified composition and quality of cemented carbide.

Milling

Milling affects both the slurry and the carbide grain's homogeneity. Therefore, milling is crucial for producing uniform cemented carbide after sintering.

Spray-drying

The slurry must be dried after milling, perhaps by spray-drying it into powder form. The components of this "Ready-To-Press" (RTP) powder are gathered into spherical agglomerates.

Blending test

The RTP-composition powder's and pressing characteristics are crucial for the subsequent process. First, the RTP-size powders and form are measured. Additionally, the powder must flow well to fill press tool cavities consistently.

Compaction

RTP powder is first pressed into compacts when cemented carbide production ramps up.

Soft Machining

Before sintering, the compacts may occasionally be softly machined or green-shaped into the appropriate shape.

Sintering

The cemented carbide receives its characteristics as a high-strength engineering material during the last process step of sintering. The sintering procedure is carried out at such a high temperature to allow the molten binder and WC to unite. High isostatic gas pressure could be used during or without the sintering (HIP).

Machining

The compact has shrunk by approximately 50% volume after the sintering. After sintering, several CC blanks are prepared for delivery. To create finished tools, blanks are machined using various techniques, such as EDM, turning, drilling, and grinding.

Quality Control

Before shipment, the cemented carbide pieces are subjected to quality control; dimensions, shape, and physical characteristics are examined before the tungsten carbide rods are approved.

Uses of Tungsten Rods

Tungsten rods are mostly used for machining tungsten components or as a tool for machining conductors, burdening steel production, and additives. In addition, they are used in advanced autos' electrodes, cylinder burdening, and crankshaft.

Properties of a Pure Tungsten Rod

- Extremely Dense: 19.25 g/cm3

- 3422 °C (6192 °F) is the high melting point.

- Exceptional Tensile Strength

- Limited Thermal Expansion Coefficient

- minimal electrical resistance

- adequate machinability

- High Capacity for Absorption

- Strong Elasticity

Choosing the Correct Tungsten Rod Supplier

To make sure you have the most positive outcome when purchasing tungsten rods from a tungsten rod supplier, it is important to compare at least 4 companies using our list of tungsten rod suppliers. Each tungsten rod supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each tungsten rod company website using our patented website preview to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple tungsten rod companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services