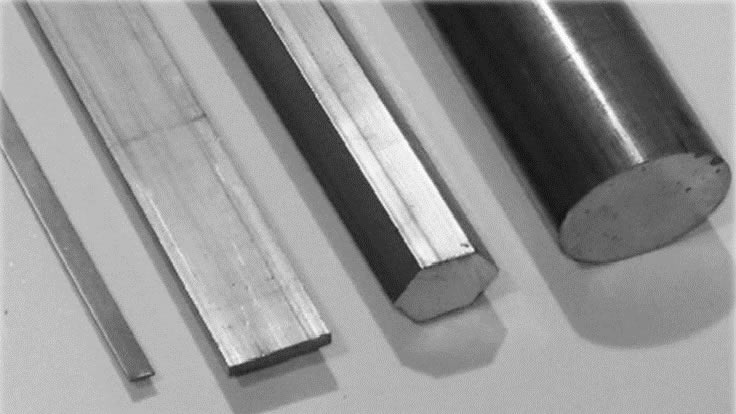

Tungsten plates are metal sheets available in various sizes and widths. After processing, tungsten plates look similar to steel. Another useful form of tungsten is recycled tungsten. A metal sheet and a metal plate can be distinguished from one another based on thickness; a sheet is less than 6mm thick while a plate is thicker than 6mm. After being mined, tungsten ore is crushed, chemically extracted, and placed in a hydrogen furnace to produce pure tungsten powder. From there, it undergoes a series of processes that compress, unite, and shape it into the appropriate form. Read More…

When you need specialty metals, run of the mill products or hard to find alloys contact Metal Associates. We are a full line distributor of metals such as aluminum. These include aluminum strip, aluminum bar, aluminum rods, 6061 aluminum, 7075 aluminum, aluminum coil, aluminum sheet, aluminum pipe, aluminum plate & aluminum tubing. We offer quality customer service & high quality products.

Elmet Technologies LLC is a 100% US owned and operated, fully integrated manufacturer of molybdenum, tungsten products and alloys. Elmet produces both flat and long/round mill products, including plate, sheet, and foil, flat rolled products, rod and wire. We have industry leading machining, fabrication, and assembly capabilities. We are a specialty metals business with over 85 years of molybdenum ...

At All Metal Sales Inc., we take pride in delivering high-quality tungsten to meet the demanding needs of industries that require exceptional strength and performance. We specialize in sourcing and distributing tungsten in a variety of forms, from raw materials to precision-engineered components, ensuring our customers receive products that excel in durability, heat resistance, and density.

At H. Cross Company, we pride ourselves on being a leading force in the fabrication and supply of precision tungsten components. With decades of experience behind us, we’ve built our reputation on the strength, reliability, and unmatched performance of our tungsten products. We understand the critical role this refractory metal plays across a wide range of demanding applications—from...

At Buffalo Tungsten, we take pride in being a leading manufacturer of high-purity tungsten powder and related products for customers around the world. We specialize in producing tungsten powders that meet the precise requirements of industries where performance, consistency, and purity are critical.

More Tungsten Plate Suppliers

Tungsten plates are used in the aerospace, construction, and electronic sectors. Tungsten plates can be found in a variety of illumination, vacuum plating, electron-vacuums, and shields in addition to their regular application in furnace building. They are also crucial for the production of parts for the semiconductor and electronic industries.

Production of Tungsten Plates

First, a rubber die sleeve is filled with raw material into a rubber die sleeve. It is made into an opaque solid tungsten slab. The raw material is processed into a solid powdered tungsten plate blank. Then manufacturers use a cold isostatic press to form the blank into a solid plate using a cold isostatic press. The press applies pressure ranging from 300 to 400 MPa. After 8–10 minutes, a solid panel blank molding is created.

Next, the solid plate blank is inserted into an sintering furnace. After heating, formed blank is cooled through water circulation. The produced plate blank is heated for two to three hours at a temperature between 1300 and 1400 degrees Celsius. To complete the production of the huge, single, and heavy tungsten plate, the heated formed plate blank is removed and rolled by a hot rolling machine. A tungsten plate target is compact and with a 99.95% relative density. Finally, the large material tungsten plate is finished after being sliced to the desired size.

Applications of Tungsten Plates

Due to their high melting points and high strengths, tungsten, and its alloys are utilized in a variety of high-temperature applications, such as turbine blades in generators and aircraft engines. High-temperature alloys are also widely used to make parts for tungsten plate furnaces.

Radiation Shield: Tungsten alloys are the best material for radiation protection because it has high density, radiation absorption, a high melting point, and superior corrosion resistance.

X-Ray Target: The most common target material for x-ray generating is tungsten. Due to tungsten's high atomic number, at a given voltage and current, x-ray intensity is increased. The x-ray anode can also become white-hot thanks to its high melting point.

Choosing the Proper Tungsten Plate Manufacturer

To make sure you have the most beneficial outcome when purchasing tungsten plates from a tungsten plate manufacturer, it is important to compare at least 4 manufacturers using our tungsten plate directory. Each tungsten plate manufacturer has a business profile page that high lights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote Review each tungsten plate business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple tungsten plate businesses with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services