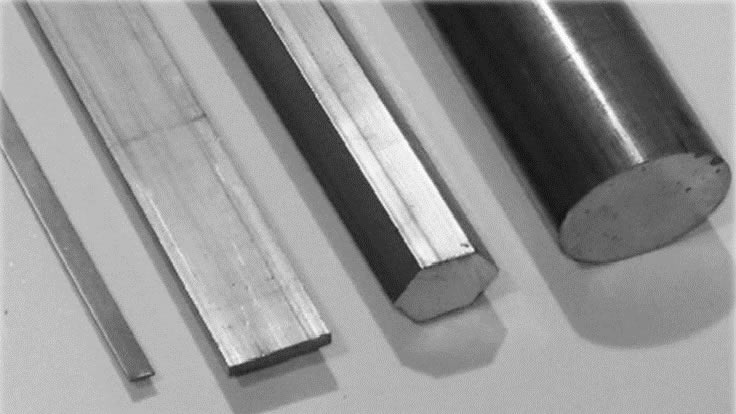

Tungsten, originally meaning heavy stone, is unique because it has the highest melting point compared to all other known elements. This high melting point of 6,191°F (3,422°C) is possible through the strength of the elements electronic bonds. Tungsten also has a very high density of 19.25 g/cm3 and a hardness level of 7.5 Mohs. All of these attributes contribute to the overall advantages associated with tungsten. Products like tungsten bar, rod, sheet and plate are continuously under experimentation for a full range of applications from military purposes such as cannon shells and new missiles to fishing lures or strings for musical instruments.

There are many different tungsten alloys. One such alloy is a combination of tungsten and rhenium which greatly increases the strength of the tungsten. The tungsten-rhenium alloys are actually more ductile and easier to machine at lower temperatures as well. The structure is extremely stable at high temperatures and used in thermocouples to accurately determine temperatures up to nearly 4,000°F. Tungsten rod can also be designed with energized hydrogen which protects the item from damage during oxidation.

Interestingly enough an innovated style of tungsten manufacturing involves using tungsten carbide drawing dies. These drawing dies are utilized to reduce the cross section of the tungsten rod by forcing the rods through drawing plates. The process is recognized for speed, outstanding erosion resistance, high thermal conductivity and an excellent cost to performance ratio. These benefits will continue to expand as tungsten rod drawing dies not only save in energy costs but also provide overall increased efficiency.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services