Tungsten foil is a type of metal foil consisting of tungsten. It has a flat, smooth surface with a black metallic sheen. Tungsten sheets are cold rolled to a thinner thickness to create tungsten foil. Stamped and drawn tungsten foil are used in high-temperature vacuum furnaces, coating, electronics, and semiconductor components. Heat shielding, heating elements, and vacuum furnace carriers are made of tungsten foil. The foil’s thinness makes it ideal for implanting in laminates, other metals, and glass. Read More…

When you need specialty metals, run of the mill products or hard to find alloys contact Metal Associates. We are a full line distributor of metals such as aluminum. These include aluminum strip, aluminum bar, aluminum rods, 6061 aluminum, 7075 aluminum, aluminum coil, aluminum sheet, aluminum pipe, aluminum plate & aluminum tubing. We offer quality customer service & high quality products.

Elmet Technologies LLC is a 100% US owned and operated, fully integrated manufacturer of molybdenum, tungsten products and alloys. Elmet produces both flat and long/round mill products, including plate, sheet, and foil, flat rolled products, rod and wire. We have industry leading machining, fabrication, and assembly capabilities. We are a specialty metals business with over 85 years of molybdenum ...

At All Metal Sales Inc., we take pride in delivering high-quality tungsten to meet the demanding needs of industries that require exceptional strength and performance. We specialize in sourcing and distributing tungsten in a variety of forms, from raw materials to precision-engineered components, ensuring our customers receive products that excel in durability, heat resistance, and density.

At H. Cross Company, we pride ourselves on being a leading force in the fabrication and supply of precision tungsten components. With decades of experience behind us, we’ve built our reputation on the strength, reliability, and unmatched performance of our tungsten products. We understand the critical role this refractory metal plays across a wide range of demanding applications—from...

At Buffalo Tungsten, we take pride in being a leading manufacturer of high-purity tungsten powder and related products for customers around the world. We specialize in producing tungsten powders that meet the precise requirements of industries where performance, consistency, and purity are critical.

More Tungsten Foil Suppliers

Comprehensive Guide to Tungsten Foil: Features, Manufacturing, and Applications

Tungsten foil, a specialized product derived from high-purity tungsten, plays a pivotal role across various industries due to its unique combination of physical and chemical properties. As a leading material for high-temperature and demanding environments, tungsten foil is essential for applications in electronics, aerospace, medical technology, and advanced manufacturing. This guide explores the key features of tungsten foil, details its manufacturing process, discusses its diverse industrial and research uses, and provides essential tips for selecting the best tungsten foil supplier for your needs.

Tungsten Foil Features

- Tungsten sheets exhibit a glittering silver shine on their surface, reflecting their high purity and quality.

- Tungsten foils offer radiation shielding properties comparable to traditional lead plates, making them a safer and more environmentally friendly alternative for radiation protection.

- Tungsten sheets are easier to manufacture and fabricate than lead due to their malleability at thin gauges, allowing them to be cut with standard tools such as household scissors while maintaining superior strength.

- The foil is robust enough to withstand repeated bending, folding, and mechanical stress without cracking, supporting long-term reliability in demanding environments.

- Tungsten foil is user-friendly, non-toxic, and poses no environmental hazards, supporting green initiatives and compliance with environmental regulations.

- Exceptional thermal plasticity enables tungsten foil to be molded into complex shapes, including cylinders and intricately curved surfaces, facilitating custom solutions for specialized engineering challenges.

- Outstanding corrosion resistance and chemical stability make tungsten foil ideal for use in aggressive or reactive environments, including acids and high-vacuum conditions.

- The ultra-high melting point (over 3420°C) and low vapor pressure ensure consistent performance in extreme heat and vacuum applications.

- Tungsten foil offers high electrical conductivity, making it suitable for electrical and electronic components requiring precision and reliability.

- Excellent dimensional stability ensures that tungsten foil maintains its shape and integrity even under thermal cycling and mechanical loads.

Did you know? When compared to other refractory metals such as molybdenum or tantalum, tungsten foil stands out for its unmatched density and heat resistance, making it the material of choice for critical high-temperature applications.

Tungsten Foil Production Process

The tungsten sheet is meticulously cold rolled to achieve the ultra-thin dimensions required for tungsten foil. The production journey begins with powder metallurgy: high-purity tungsten ore is processed into powder, then compacted into bar shapes. These bars undergo a series of hot or cold rolling steps, gradually reducing their thickness while enhancing structural integrity.

Throughout production, advanced vacuum annealing furnaces are employed for controlled heating and cooling cycles. This critical step relieves internal stresses, optimizes grain structure, and enhances the physical properties of the tungsten. Further, specialized rolling mills, straighteners, hydraulic plate shears, precision water jets, and pressing machines are utilized to transform tungsten into ultra-thin foils. The sintering process is essential, as it densifies the tungsten bars and primes them for high-performance use.

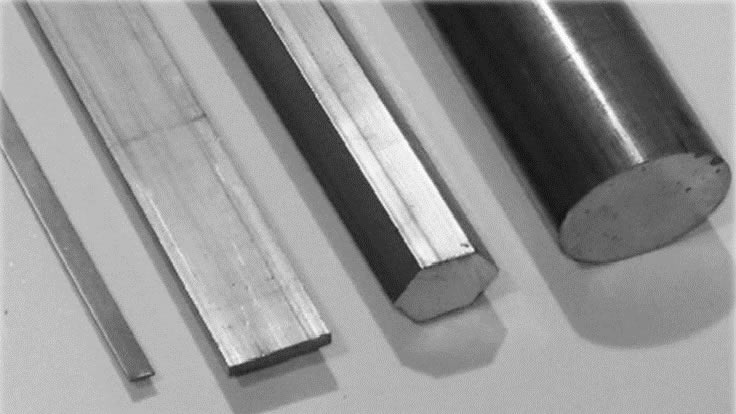

Tungsten bar stock is processed through powerful rolling presses, applying immense pressure to consolidate tungsten particles and achieve the desired foil thickness—sometimes as thin as 0.001 inches. Tungsten foil is supplied in a variety of forms, including sheets, coils, and custom cut-to-length strips to meet specific project requirements. Surface finishes can range from matte to mirror-bright, with typical foils closely resembling the luster of stainless steel.

What Are the Primary Uses and Applications of Tungsten Foil?

Tungsten foil is renowned for its exceptional performance in environments requiring resistance to extreme temperatures, aggressive chemicals, and intense mechanical stress. Its unique combination of durability, thermal stability, and electrical conductivity makes it indispensable across a wide spectrum of industries. Below, we highlight the most common and emerging applications for tungsten foil:

- High-Temperature Furnace Components: Tungsten foil is ideal for fabricating furnace pillars, heat shields, and boat liners in vacuum and inert atmosphere furnaces, where conventional materials would fail.

- Radiation Shielding: Thanks to its high density and non-toxicity, tungsten foil serves as an effective alternative to lead for radiation shielding in medical imaging rooms, nuclear research facilities, and aerospace applications.

- Electronics and Semiconductor Manufacturing: Tungsten foil is a key material for evaporation boats, heating elements, and sputtering targets in thin-film deposition and semiconductor fabrication processes.

- Lighting and Electrovacuum Industries: Tungsten foil is used in the production of electric vacuum devices, filaments, and support structures for electric light sources, including halogen lamps and X-ray tubes.

- Medical and Scientific Research: Its biocompatibility and radiopacity make tungsten foil suitable for medical imaging, radiation therapy equipment, and specialized scientific instruments.

- Advanced Manufacturing: Tungsten foil is utilized for producing wear-resistant coatings, precision fasteners (bolts, screws), and ion implantation components essential to modern manufacturing and material science.

- Glass and Quartz Processing: The foil is used for stirring bars, headgear, and fixtures in high-temperature glass, rare-earth, and quartz industries.

- Custom Engineering Solutions: Due to its formability and resilience, tungsten foil is increasingly employed in aerospace, defense, and automotive sectors for custom shielding, electronic packaging, and micro-mechanical assemblies.

- Emerging Applications: As research advances, tungsten foil is being explored for fuel cell technology, energy storage devices, and as a component in next-generation flexible electronics.

Searching for a specific tungsten foil application?

Many users explore:

- How is tungsten foil used in semiconductor manufacturing?

- What thickness of tungsten foil is best for radiation shielding?

- Can tungsten foil be customized for unique furnace designs?

- Is tungsten foil suitable for biomedical or pharmaceutical uses?

Key Benefits of Tungsten Foil for Industrial and Research Use

- Extreme Temperature Tolerance: With a melting point above 3420°C, tungsten foil outperforms most metals in high-heat environments, ensuring reliability in thermal processing and vacuum furnace operations.

- Superior Radiation Shielding: Its high atomic number and density provide effective gamma and X-ray shielding, without the toxicity of lead, making it the preferred choice for radiation safety.

- Exceptional Mechanical Strength: Even at thin gauges, tungsten foil maintains mechanical integrity, supporting repeated use, forming, and complex fabrication processes.

- Corrosion and Chemical Resistance: Tungsten foil resists oxidation, acids, and aggressive chemicals, extending service life in harsh environments.

- Electrical and Thermal Conductivity: The high conductivity of tungsten foil supports its use in advanced electronics, power distribution, and precision heating elements.

- Environmental Safety: Unlike lead, tungsten is non-toxic and environmentally benign, aligning with sustainable manufacturing and regulatory compliance.

- Customizability: Tungsten foil can be tailored in thickness, width, and surface finish to meet the exact requirements of your application.

- Dimensional Stability: Minimal thermal expansion and high structural integrity make tungsten foil ideal for precision components.

How to Select the Right Tungsten Foil for Your Application

Selecting the optimal tungsten foil involves evaluating several critical factors to ensure the material meets your technical, operational, and regulatory requirements. Here are key considerations for buyers, engineers, and procurement specialists:

- Purity Level: Verify the tungsten content (typically ≥99.95%) to ensure maximum performance, especially in semiconductor, medical, and aerospace applications.

- Thickness and Dimensions: Choose the appropriate foil thickness and width based on your application's requirements for flexibility, shielding, or structural support. Common thicknesses range from 0.001" to 0.1".

- Mechanical Properties: Consider tensile strength, elongation, and hardness, which affect the foil's formability and durability under stress.

- Surface Finish: Select from matte, bright, or custom finishes depending on reflectivity, cleanliness, or bonding needs.

- Certifications: Confirm compliance with ASTM, ISO, or other relevant standards for quality assurance and traceability.

- Customization Options: Many suppliers offer custom cutting, slitting, and fabrication to match your design specifications.

- Lead Time and Availability: Assess supplier inventory and production capabilities to ensure timely delivery for your project timeline.

- Cost Efficiency: Compare pricing structures, minimum order quantities, and bulk discounts to optimize your material budget.

- Supplier Support: Evaluate technical support, documentation, and after-sales services provided by the tungsten foil manufacturer.

Not sure which tungsten foil specification is right for your project?

Request a quote or contact our support team for expert guidance and personalized recommendations.

Choosing the Right Tungsten Foil Supplier

To ensure the most productive outcome when purchasing tungsten foil, it’s important to partner with a supplier that demonstrates expertise, quality assurance, and a commitment to customer service. Our comprehensive tungsten foil directory allows you to efficiently compare at least 5 leading tungsten foil companies. Each business profile showcases unique areas of experience, material certifications, processing capabilities, and specialized services tailored to your industry’s needs.

- Review each tungsten foil supplier’s website using our patented website previewer to quickly evaluate their specialties, product range, and technical resources.

- Leverage the built-in contact forms to request detailed information, technical datasheets, or a custom quote without leaving our directory platform.

- Use the streamlined RFQ (Request for Quote) tool to send a single message to multiple suppliers, saving valuable time in your sourcing process.

Looking for trusted tungsten foil suppliers?

Browse our directory or submit your RFQ to connect with pre-qualified manufacturers and distributors.

Frequently Asked Questions About Tungsten Foil

- What is the typical lead time for custom tungsten foil orders?

Lead times vary by thickness and volume, but most suppliers fulfill standard orders within 2–4 weeks. Custom fabrication may require additional processing time. - How can I test the purity and quality of tungsten foil?

Reputable suppliers provide certificates of analysis and comply with ASTM or ISO standards. Third-party material testing and verification are also available for critical applications. - Can tungsten foil be welded or brazed?

Yes, tungsten foil can be joined using specialized resistance welding or vacuum brazing techniques, but requires expertise due to its high melting point and thermal conductivity. - What are common thicknesses and tolerances for tungsten foil?

Standard thicknesses range from 0.001" to 0.1" with tight tolerances (+/- 0.0002") achievable through precision rolling and inspection. - Is tungsten foil available with surface treatments or laminations?

Many suppliers offer surface treatments (e.g., cleaning, etching) and can laminate tungsten foil with other metals or polymers for hybrid applications. - What safety precautions should be taken when handling tungsten foil?

Tungsten is non-toxic, but thin foils may have sharp edges; handle with gloves and use protective eyewear during cutting or fabrication.

Have more questions about tungsten foil?

Contact our technical team.

Industry Trends and Future Directions for Tungsten Foil

The demand for tungsten foil is growing rapidly, fueled by advancements in semiconductor manufacturing, the shift toward eco-friendly radiation shielding, and emerging applications in sustainable energy and flexible electronics. Researchers are developing next-generation tungsten foil composites with improved mechanical properties and surface functionalization for use in aerospace, defense, and medical implants. Digital transformation and Industry 4.0 manufacturing are streamlining production, enabling tighter tolerances and greater design flexibility.

Interested in the future of refractory metals and advanced materials?

Discover more about innovations in tungsten sheet, tungsten bar, and related tungsten products on our website.

Why Choose Tungsten Foil for Your Next Project?

Whether you’re engineering next-generation electronics, designing radiation-proof enclosures, or developing advanced medical devices, tungsten foil offers unmatched performance, reliability, and value. Its unique properties—high melting point, strength, chemical stability, and safety—make it the material of choice for mission-critical applications across modern industry.

Ready to take the next step? Request a quote or contact us today to discuss your specific tungsten foil requirements with our experienced team. Leverage our expertise and supplier network to source the highest quality tungsten foil for your industrial, research, or commercial project.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services