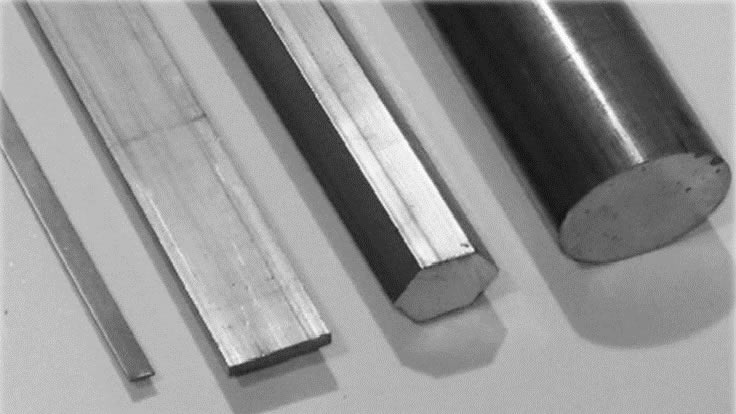

A Tungsten bar is made from 99.90% pure tungsten powder shaped into rounds and rectangles. It has a shiny, white metal surface and a density of over 17.5g/cm3. Tungsten bars are mainly used as additives in steel production or for spare parts in the semi-conductive and welding industries. Read More…

When you need specialty metals, run of the mill products or hard to find alloys contact Metal Associates. We are a full line distributor of metals such as aluminum. These include aluminum strip, aluminum bar, aluminum rods, 6061 aluminum, 7075 aluminum, aluminum coil, aluminum sheet, aluminum pipe, aluminum plate & aluminum tubing. We offer quality customer service & high quality products.

Elmet Technologies LLC is a 100% US owned and operated, fully integrated manufacturer of molybdenum, tungsten products and alloys. Elmet produces both flat and long/round mill products, including plate, sheet, and foil, flat rolled products, rod and wire. We have industry leading machining, fabrication, and assembly capabilities. We are a specialty metals business with over 85 years of molybdenum ...

At All Metal Sales Inc., we take pride in delivering high-quality tungsten to meet the demanding needs of industries that require exceptional strength and performance. We specialize in sourcing and distributing tungsten in a variety of forms, from raw materials to precision-engineered components, ensuring our customers receive products that excel in durability, heat resistance, and density.

At H. Cross Company, we pride ourselves on being a leading force in the fabrication and supply of precision tungsten components. With decades of experience behind us, we’ve built our reputation on the strength, reliability, and unmatched performance of our tungsten products. We understand the critical role this refractory metal plays across a wide range of demanding applications—from...

At Buffalo Tungsten, we take pride in being a leading manufacturer of high-purity tungsten powder and related products for customers around the world. We specialize in producing tungsten powders that meet the precise requirements of industries where performance, consistency, and purity are critical.

More Tungsten Bar Suppliers

Tungsten Bars: Physical and Chemical Properties

Tungsten bars, also referred to as tungsten rods or tungsten billets, are a critical component in industries requiring exceptional material performance under extreme conditions. They are manufactured in three main grades: TW-1, TW-2, and TW-4. Understanding the differences between these grades is essential for selecting the right tungsten bar for your specific application:

- TW-1: Primarily utilized for manufacturing spare parts in the semiconductor, welding, and electronics industries due to its high purity and consistency.

- TW-2: Used as a processing raw material for advanced metallurgical applications and component fabrication.

- TW-4: Serves as an additive in the steel manufacturing industry, enhancing the strength, hardness, and heat resistance of specialty steels and superalloys.

Each tungsten bar, regardless of grade, boasts a minimum density of 17.5g/cm³, making it one of the densest and most robust metallic materials available. This high density contributes to its prized mechanical properties in demanding environments. Under typical atmospheric conditions, tungsten bars exhibit remarkable chemical stability, showing no reactivity with water, air, or sulfuric acid (HCl). However, at elevated temperatures (around 80°C to 100°C), they may begin to react mildly with acids. Tungsten’s susceptibility to oxidation increases significantly in oxygen-rich environments at high temperatures, a factor to consider when specifying materials for high-heat or oxidative processes.

How Are Tungsten Bars Manufactured?

(Tungsten Bar Production Process Explained)

The production of tungsten bars involves sophisticated powder metallurgy techniques, designed to maximize material utilization and produce bars with exceptional purity and performance. Understanding the manufacturing process is vital for buyers seeking high-quality tungsten bars for critical applications. If you’re wondering, “How are tungsten bars made?” or “What is powder metallurgy for tungsten?”, explore the detailed steps below:

-

Ore Reduction to Tungsten Powder:

The process begins with the extraction and reduction of tungsten ore (typically scheelite or wolframite) to a fine powder. The powder’s particle size and morphology are closely controlled, as they directly influence the final product’s mechanical and physical characteristics.

-

Chemical Processing and Oxide Formation:

Through a series of chemical reactions, the tungsten powder is converted into tungsten oxide (WO3). This step ensures the removal of impurities and achieves the desired composition for subsequent reduction.

-

Hydrogen Reduction to Pure Tungsten:

Tungsten oxide is then reduced in a hydrogen atmosphere at high temperatures, resulting in pure tungsten powder. This high-purity tungsten powder is the key precursor for manufacturing advanced tungsten products.

-

Compaction and Molding:

The pure tungsten powder is poured into precision molds and hydraulically pressed to form a green (unsintered) bar shape. The compaction process is crucial for achieving the target density and uniformity.

-

Sintering:

The molded bars undergo sintering—a high-temperature process that consolidates the powder particles, increasing density and mechanical strength. Sintering typically occurs in a hydrogen or inert gas atmosphere to prevent oxidation and contamination.

-

Post-Sintering Processing:

Depending on the final application, tungsten bars may be rolled, drawn, forged, or machined to precise specifications. Additional surface treatments or alloying steps may be employed to enhance specific properties (e.g., ductility, surface finish, hardness).

The meticulous control of each stage ensures that finished tungsten bars meet strict quality standards for purity, structure, and mechanical performance. For industries demanding high reliability—such as aerospace, electronics, and defense—these rigorous processes are non-negotiable.

Industrial and Commercial Applications of Tungsten Bars

Tungsten bars are an essential material in a diverse range of high-tech industries. Their unique combination of density, melting point, and chemical stability makes them ideal for applications where conventional metals fail. Wondering, "What are tungsten bars used for?" or "Which industries rely on tungsten bars?" Here are some of the most common and advanced uses:

-

High-Performance Alloy Production:

- Tungsten bars (especially 99.999% pure) serve as a key alloying element in high-speed steels, tool steels, and superalloys for aerospace, automotive, and energy industries.

-

Manufacture of Precision Components:

- Utilized in the fabrication of components for automobiles, high-speed trains, and extremely precise measuring equipment where dimensional stability is critical.

-

Defense and Ballistics:

- Tungsten’s high density and hardness make it the material of choice for kinetic energy penetrators, armor-piercing ammunition, artillery shells, and advanced weapons systems.

-

Electronics and Semiconductor Manufacturing:

- Applied in the production of semiconductor devices, X-ray targets, vacuum tube electrodes, electrical contacts, and filaments for lighting and electronic equipment.

-

Crystal Growth and Furnace Construction:

- Critical in the construction of furnaces for sapphire crystal production, high-vacuum, and high-temperature environments where material integrity is paramount.

-

Marine and Aerospace:

- Employed in shipbuilding, satellite components, aerospace structures, and rocket or missile systems, where strength-to-weight ratio and durability are key.

-

Medical and Radiation Shielding:

- Used for radiation shielding in medical imaging, cancer therapy, and nuclear research due to tungsten’s high atomic number and density.

-

Jewelry and Counterfeit Prevention:

- Valued for manufacturing wear-resistant jewelry and as a gold substitute due to its similar density and lower cost; also used in anti-counterfeit applications.

The versatility of tungsten bars is reflected in their widespread adoption for specialized, high-value products. If your industry demands refractory metals able to withstand extreme mechanical, chemical, or thermal stress, tungsten bars are likely the optimal choice.

Advantages and Unique Benefits of Tungsten Bars

1. Extreme Temperature Resistance

Tungsten holds the record for the highest melting point among all metals at 3422°C (6192°F). This property makes tungsten bars indispensable in environments subject to intense heat, such as aerospace propulsion, glass melting, and high-temperature furnaces. Tungsten’s low vapor pressure at elevated temperatures ensures structural integrity where most metals would fail or volatilize.

2. Exceptional Density and Mass Efficiency

With a density 1.7 times greater than lead, tungsten bars deliver unmatched mass in compact dimensions. This high-density characteristic is essential in kinetic energy penetrators, ballast weights for aircraft and racing vehicles, and vibration-damping components where weight distribution must be precise without sacrificing space.

Did you know? Tungsten’s density is only marginally less than gold, but it’s significantly more cost-effective. This makes tungsten a popular choice for creating counterfeit gold bars and for manufacturing high-end jewelry that mimics gold’s heft and feel at a fraction of the price.

3. Low Thermal Expansion and Dimensional Stability

Tungsten features the lowest coefficient of thermal expansion among pure metals. This means tungsten bars retain their shape and size even when exposed to rapid temperature fluctuations—a critical requirement for high-precision tools, molds, and structural components in demanding thermal environments.

4. Superior Electrical Conductivity and Radiation Shielding

Thanks to its unique electronic structure, tungsten is an excellent electrical conductor and is widely used in environments with high radiation levels. Tungsten’s high atomic number and density make it an effective shield against X-rays and gamma rays, which is why tungsten bars are used in the construction of X-ray targets, radiation therapy equipment, and nuclear research facilities.

5. Chemical and Corrosion Resistance

Tungsten bars exhibit outstanding resistance to corrosion by most acids and alkalis, especially under ambient conditions. This inertness extends the service life of tungsten products in aggressive chemical processing, electroplating, and marine environments.

6. Recyclability and Sustainability

Tungsten’s high value and relative scarcity have driven robust recycling programs worldwide. Used tungsten bars and scrap can be efficiently reclaimed and reprocessed, supporting sustainability initiatives in manufacturing and reducing reliance on primary mining.

Buyer’s Guide: How to Select the Right Tungsten Bar

Choosing the best tungsten bar for your needs requires careful consideration of several technical and commercial factors. If you’re wondering, “What should I look for when buying tungsten bars?”, these are the decision points to focus on:

- Purity Grade: Higher purity bars (e.g., 99.95% or 99.999%) are necessary for electronics, medical, and aerospace applications, while lower grades may suffice for less critical industrial uses.

- Dimensions and Tolerances: Specify precise diameter, length, and surface finish requirements. Tighter tolerances are needed for machining, electronics, and toolmaking.

- Mechanical Properties: Assess required hardness, tensile strength, ductility, and impact resistance based on your project’s performance needs.

- Chemical Compatibility: Consider the operating environment—temperature, exposure to corrosive chemicals, and atmospheric conditions.

- Certification and Compliance: Request documentation such as mill test reports (MTRs), certificates of analysis (CoA), and compliance with industry standards (ASTM, ISO, AMS, etc.).

- Supplier Reputation and Support: Source tungsten bars only from qualified, reputable manufacturers with a track record of consistent product quality, technical support, and reliable delivery.

Need to compare suppliers? See our curated list of tungsten bar manufacturers and use our RFQ form to request quotes directly from multiple vetted companies.

Choosing the Right Tungsten Bar Manufacturer: Key Considerations

To achieve the most beneficial outcome when purchasing tungsten bars, it’s critical to compare at least 5 different tungsten bar manufacturers or suppliers. Each manufacturer has unique strengths, capabilities, and specialties, so evaluating your options ensures you find the best fit for your technical and budgetary requirements. Here’s how to streamline your selection process:

- Review Manufacturer Profiles: Each tungsten bar manufacturer features a business profile page highlighting their areas of expertise, production capacity, industry certifications, and material offerings.

- Direct Communication: Use dedicated contact forms to request further information, technical datasheets, or custom quotes. This helps clarify lead times, pricing structures, and support services.

- Evaluate Specializations: Some manufacturers focus on high-purity tungsten bars for electronics and medical applications, while others excel in producing large-diameter bars or custom alloys for industrial uses.

- Check Quality Assurance: Investigate quality control processes, supply chain transparency, and after-sales support to minimize risk and ensure ongoing satisfaction.

- Use Our Website Previewer: Take advantage of our proprietary website previewer to quickly assess each business’s specialties and capabilities before making direct contact.

- Submit a Unified RFQ: Our simple RFQ (request for quote) form allows you to contact multiple tungsten bar manufacturers simultaneously, streamlining your sourcing process and enabling competitive pricing.

Curious about bulk pricing or custom dimensions? Contact manufacturers directly to discuss your project requirements, bulk order discounts, and lead times for specialty tungsten bars.

Frequently Asked Questions About Tungsten Bars

- What are the main differences between tungsten bars and tungsten rods?

While both forms are derived from the same material and processes, “tungsten bars” generally refer to larger, bulk forms used as stock for machining or alloy production, whereas “tungsten rods” are typically smaller diameter, precision-rolled products used directly in manufacturing or as electrodes. - Where can I buy tungsten bars online?

Tungsten bars can be sourced from specialized metals suppliers, industrial distributors, and directly from reputable manufacturers. Always verify supplier credentials and request certification for quality assurance. - How do I specify custom tungsten bars for my application?

Provide detailed drawings or technical specifications, including grade, dimensions, tolerances, and any additional property requirements (e.g., surface finish, alloying elements). - Are tungsten bars recyclable?

Yes, tungsten is highly recyclable. Many suppliers offer buyback or recycling programs for used or scrap tungsten bars, supporting sustainability and efficient resource utilization. - What is the typical lead time for tungsten bar orders?

Lead times depend on purity level, dimensions, and quantity. Standard sizes may be available from stock, while custom orders can require several weeks of lead time. Early communication with suppliers helps ensure timely delivery. - Can tungsten bars be machined or welded?

Tungsten is machinable using specialized carbide tools and techniques due to its hardness and brittleness. Welding is possible under controlled conditions, typically by professionals using inert atmospheres to prevent oxidation and embrittlement.

Explore Further: Related Tungsten Products and Resources

Looking for more information about tungsten and refractory metals? Explore our extensive guides and resources on:

- Tungsten Powder: Grades, Uses, and Supplier Selection

- Tungsten Rods: Manufacturing, Grades, and Industrial Uses

- All Tungsten Supplier Resources

Not sure which tungsten product is right for your project?

Contact our experts for personalized recommendations, technical support, and sourcing assistance.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services